- Posts: 3082

- Thank you received: 2371

Bugs: Recent Topics Paging, Uploading Images & Preview (11 Dec 2020)

Recent Topics paging, uploading images and preview bugs require a patch which has not yet been released.

3D printed miniatures are the future.

- Cranberries

-

Topic Author

Topic Author

- Offline

- D10

-

- Don't give up.

There's already a guy on BGG who will make out-of-print games on demand, but you're looking at 80 bucks for Dune, I believe. So perhaps the cost of using a third party for DIY miniatures will still be too high. I mean, who needs a corner mini-printer when you have China?

Look at the cost for ink if you want to print out something at home. My guess is that when decect 3d printers start showing up at work, then "free" minis will start cropping up.

I actually watched that third video, "Figure Printing" and there is some serious hardware behind making those large Warcraft dolls. I didn't understand the machine that was immersing them in something--the "Super Bee." Is that just varnish?

It's interesting to think about the intersection of advancing technology, countries like China and cheap global distribution. Did you know that giant cargo ships are more fuel efficient that your Prius?

Please Log in or Create an account to join the conversation.

I doubt that this would grow exponentially like computers. This is physical stuff. I know many independent miniature makers who use 3D prints, but not for mass production. They make a 3d print, clean it up, and finally use it to create the mold. Slight mistakes in cleaning will cause the ridge lines to appear (sometimes worse) on the metal mass production copies.

I've held low quality 3d prints and high quality 3d prints in my hands. Even the best just don't compare with FFG new crop of plastics. And to say nothing about Games Workshop quality, which is still leap and bounds above most competitors.

Please Log in or Create an account to join the conversation.

Sevej wrote: I've held low quality 3d prints and high quality 3d prints in my hands. Even the best just don't compare with FFG new crop of plastics. And to say nothing about Games Workshop quality, which is still leap and bounds above most competitors.

Quality of the prints? Or quality of the medium?

I've venture a guess, and were I a betting man I'd bet the farm, that FFG is now using 3D printing for their prototyping and masters.

Please Log in or Create an account to join the conversation.

Masters (meaning the models they make the molds from) printed in metal (I'm pretty sure brass, but it doesn't look brass so I need to double check) of the troops:

https://fbcdn-sphotos-g-a.akamaihd.net/hphotos-ak-xap1/v/t1.0-9/24304_195744847259085_1520800731_n.jpg?oh=01c3f0982342658ab526f68e14a5d346&oe=55456F39&__gda__=1429091345_845e28e89ee455741d60725734f7f145

Masters of the dreadnought sized walker troops, these are about 3/4" tall:

https://scontent-a-ord.xx.fbcdn.net/hphotos-xaf1/v/t1.0-9/408508_164516637048573_2121722322_n.jpg?oh=f8a9ef4a1ac492578fbe547163c64fa2&oe=553DCC37

Here are prototypes for his signoff in plastic prior to the masters being printed up:

https://fbcdn-sphotos-g-a.akamaihd.net/hphotos-ak-xaf1/v/t1.0-9/1011433_179117968921773_1904774520_n.jpg?oh=68dc257caf21971579d091942d435b36&oe=553B1FC8&__gda__=1430387995_9fb0613449538af1b22830e3093d8ba2

And I'll need to double check if these are the masters or the finished product just primed and a quick wash.

https://fbcdn-sphotos-d-a.akamaihd.net/hphotos-ak-ash2/v/t1.0-9/1454837_228529110647325_173396504_n.jpg?oh=219679fd6bac408265e9a7b6fe73f72b&oe=552E101A&__gda__=1429250493_1ecbcebd980e1c455520a334d08a00b5

Keep in mind the scale of these, being as small as they are, it is not possible to put in that level of detail using traditional armatures and green-stuff modeling epoxy.

When sculpting in 3D you can zoom the model in and add details that you just can't get by manipulating and pushing medium, that's why the model quality is getting better and better because this technology is getting more accessible. Back 10 years ago everything was sculpted by hand but with Rakham/Confrontation the rumor was that their detail was achieved by computer modeling and 3D printing, but they kept their process under wraps, and this was during a time when everyone sculpted by hand.

10 years later, using a few subcontractors my buddy is able to run a miniatures company out of his basement.

Now...This addresses just the prototyping and master model creation, the finished product is still cast in pewter. But 10 years from now I wouldn't be surprised to see him investing in some at home printing to cut out his subcontractors.

EDIT: Damn, photos won't embed, I'll try to figure out later but my 2yo is running around like a dang fool demanding attention. I'll try to fix later, till then just cut and paste.

Please Log in or Create an account to join the conversation.

- Cranberries

-

Topic Author

Topic Author

- Offline

- D10

-

- Don't give up.

- Posts: 3082

- Thank you received: 2371

This is why Facebook is terrible. Not only does it reduce the images to the level of crap, but it won't even let you link to it. It's like locking turds in a safe. Not only that, but your friend's great stuff can't even be found using an image search tool like Tineye.

He should have a tumblr or something.

Please Log in or Create an account to join the conversation.

It's a combination of both the method and the material. Most still uses a layer method, and it needs material that can maintain edges & details, while still being viable to be CNC-ed.

And yes, it works better for smaller scale miniatures. I know people who're buying 3mm tanks off Shapeways. They don't have to worry much about graininess, and the surfaces tend to be small. Larger scales such as 28mm or even 1/72 needs that comparatively large smooth surfaces. These large smooth surfaces can be a pain to clean up, especially if they're curved.

I know for sure Dreamforge Games, Malifaux, Games Workshop and Corvus Belli use CAD design, but only CB uses 3D prints because they use metal for the final miniatures. So I wouldn't be surprised if FFG uses CAD design, but not 3D printing.

EDIT: Please differentiate between 3D printing & rapid prototyping.

Please Log in or Create an account to join the conversation.

Early arguments were that nothing beats good old fashioned sculpting, so much of my counter point was that many are not sculpted in the traditional sense. And detailed that currently yes, we are in rapid prototyping and sculpting online.

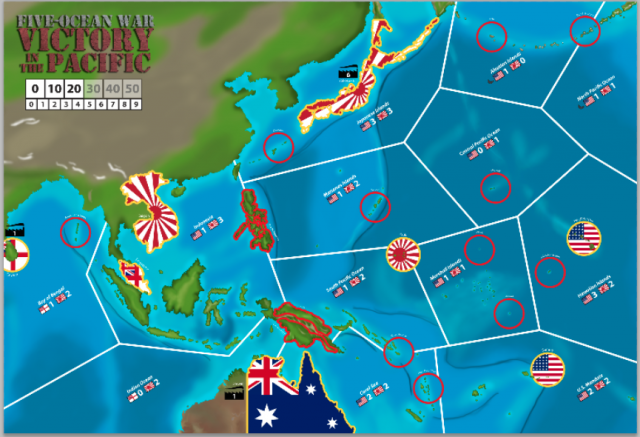

I've always liked this photo:

Yes, there are limits to the technology now. You can see the lines and layers in it, but like all technology it'll get better.

So no, no one is mass producing on any meaningful scale via 3D printing (and I don't think I claimed that but I do know I'm horrible and making my point clear), it currently all prototyping and master production. I think by the close of the 20's though (which is what I theorized upthread) printers will be cost effective and provide the resolution to make 3D printing at home possible.

I think it'll happen sooner rather than later.

Sounds like you know quite a bit about mini modeling - What's the process of making a plastic mold? I'm very familiar with the metal process, but the plastic ones I know little about. Are they milled out of a metal block?

Please Log in or Create an account to join the conversation.

My counter point would that the 3d print trend that we have right now is actually a rapid prototyping method using a LOT of shortcuts. This method gives the impression that home made 3d prints of good quality (say, FFG's quality) is near. Although yeah, an amazing breakthrough could give us a high quality 3d printer at every home. But amazing breakthroughs are quite rare. This kind of technology *will* change how the world works.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Games

Games

How to resolve AdBlock issue?

How to resolve AdBlock issue?